TMS AI Dispatch Optimization: The 45-Day Setup That Cuts Manual Overrides by 60%

Suboptimal dispatch planning decisions cost American truck fleets between $150 and $200 billion every year. You read that right. While your team debates the latest TMS features, billions drain from the industry through one persistent problem: dispatchers either rely on tribal knowledge or struggle with optimization tools that don't fit their workflow. Plans become obsolete the moment they're created. And making adjustments requires either waiting days for engineering support or manually overriding the system.

Here's the paradox that keeps supply chain executives awake: companies invest millions in AI-powered TMS dispatch optimization, only to watch load planners bypass the recommendations and make manual decisions anyway. The technology promises efficiency, but poor integration and workflow mismatches create more friction than they solve.

This isn't another vendor pitch about AI magic. This is a practical 45-day implementation framework that addresses the root causes of manual override problems while building the data architecture and workflow integration necessary for real optimization success.

The $200 Billion Manual Override Problem

The scale of inefficiency in dispatch planning staggers even industry veterans. Suboptimal dispatch planning decisions cost American truck fleets between $150 and $200 billion every year, according to recent analysis. But the real problem isn't just suboptimal decisions – it's the systematic abandonment of optimization systems by the very people they're designed to help.

Load planners override AI recommendations for predictable reasons. Poor task management can increase operational costs by 15-20%, and when optimization tools create more work rather than less, dispatchers revert to familiar manual processes. The most common override scenarios include:

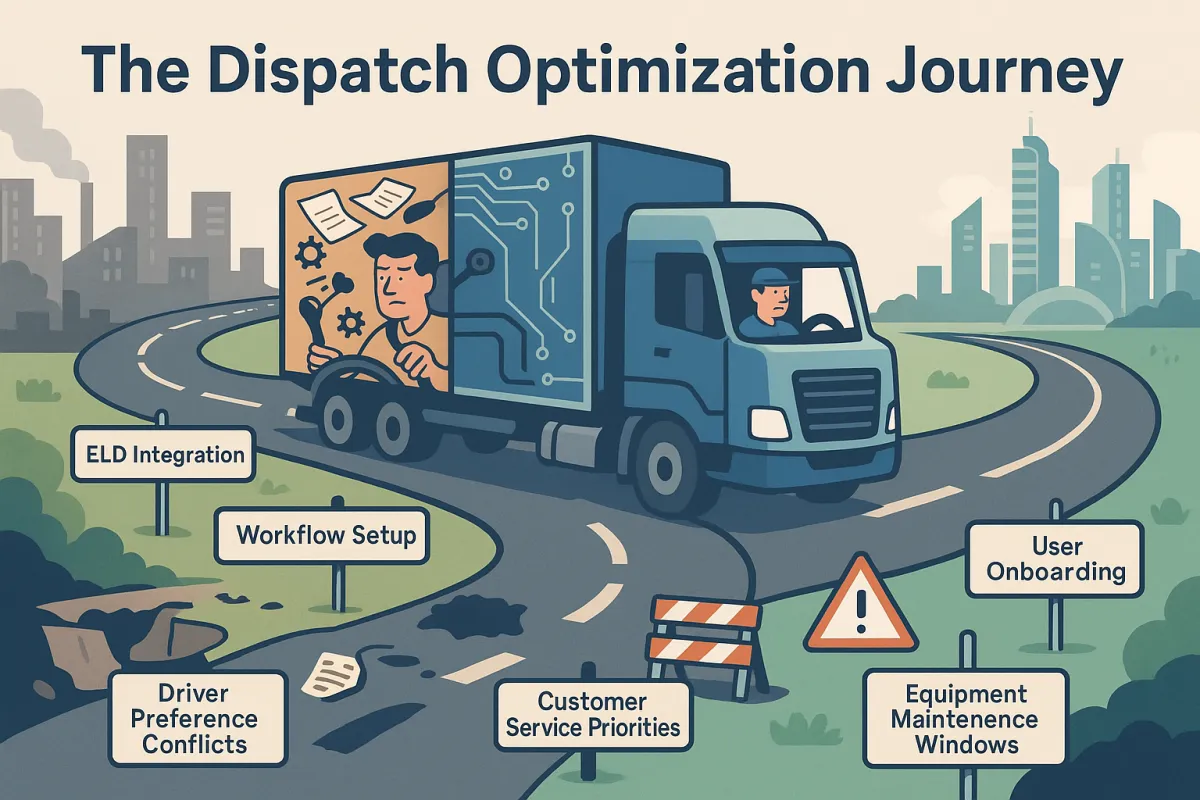

Driver preference conflicts where the system recommends assignments that ignore driver constraints or home time requirements. Customer service priorities that the AI doesn't understand, like accommodating a key account's last-minute changes. Equipment maintenance windows that aren't reflected in the optimization engine's data feeds.

Each override compounds the problem. When dispatchers consistently bypass recommendations, the AI stops learning from real operational decisions. The system becomes increasingly divorced from actual workflow requirements, creating a downward spiral of relevance and adoption.

Why AI Optimization Fails in Real TMS Environments

The fundamental issue isn't AI capability – it's integration architecture. Transportation Management Systems have tried to deliver optimization natively, but traditionally struggled because of the lack of real-time data and intuitive load planning interfaces. Most TMS implementations treat AI optimization as an add-on feature rather than a core workflow component.

Consider the data flow requirements for effective dispatch optimization. The system needs real-time feeds from ELD systems for driver hours, maintenance platforms for vehicle availability, customer portals for delivery requirements, and warehouse management systems for load characteristics. When any of these data sources lag or disconnect, plans become obsolete the moment they're created.

The workflow integration gap creates even bigger problems. Dispatchers work in familiar interfaces with established processes. When optimization recommendations appear in separate screens or require additional data entry steps, adoption fails. Companies using solutions from BeyondTrucks, Cargoson, Descartes, and MercuryGate report similar challenges: powerful optimization engines undermined by poor user experience design.

The constraint management problem compounds these issues. When something changes, whether a driver can't leave their home state, or other new delivery constraints arise, the user can flexibly adjust constraints and run the optimization again instantly. But most systems require complex configuration changes or engineering support to modify planning parameters, forcing dispatchers to work around the system rather than with it.

The 45-Day Implementation Framework

Successful TMS dispatch optimization requires a structured approach that prioritizes data architecture, workflow integration, and user adoption over feature deployment. This framework addresses the integration challenges that cause manual override problems while building the foundation for sustainable optimization success.

Days 1-15: Data Architecture & Integration Setup

The first two weeks focus on establishing reliable data flows between systems. The BeyondTrucks Optimization Solution is uniquely positioned to enhance dispatch planning by leveraging a multi-tenant architecture that combines proprietary data from their TMS with information from other systems—such as ELDs, fleet management platforms, and driver applicant tracking systems. This multi-system integration approach becomes the model for your implementation.

Start with ELD integration to ensure real-time driver availability data. Most manual overrides happen because optimization systems recommend assignments to drivers who aren't actually available or are approaching hours-of-service limits. Configure automatic data feeds from Samsara, Geotab, or similar platforms to update driver status every 15 minutes.

Establish maintenance system connections next. Vehicle downtime predictions require integration with fleet management platforms like Fleetio or AssetWorks. The optimization engine needs to exclude vehicles from recommendations 48-72 hours before scheduled maintenance windows.

Configure constraint management capabilities during week two. No data delays across systems, such as preventive maintenance scheduling solutions, navigation systems with weather information, or driver qualifications and preferences becomes the operational standard. Test constraint adjustments to ensure dispatchers can modify planning parameters without engineering support.

Days 16-30: Workflow Integration & User Interface Design

The third and fourth weeks address the workflow integration problems that drive manual overrides. Enabling real-time interaction with human load planners in their primary workspace requires custom interface development that matches existing dispatcher workflows.

Map current dispatcher processes before building new interfaces. Document how planners currently assign loads, communicate with drivers, and handle exceptions. The AI optimization recommendations must fit into these established patterns, not replace them entirely.

Design recommendation displays that provide context for AI suggestions. Instead of simply showing optimized load assignments, include the reasoning behind each recommendation and highlight constraint factors that influenced the decision. When dispatchers understand why the system made specific suggestions, they're more likely to accept them.

Solutions like nShift, Manhattan Active, Blue Yonder, and Cargoson offer different approaches to interface design, but successful implementations share common elements: single-screen visibility of recommendations and constraints, one-click acceptance or modification of suggestions, and clear escalation paths for complex scenarios.

Configure communication workflows during this phase. Clear communication with drivers is often overlooked, yet 38% of logistics firms cite it as a major issue. Miscommunication can lead to missed deadlines, incorrect deliveries, and wasted resources. Integrate messaging capabilities directly into the optimization interface so dispatchers can communicate assignment changes without switching systems.

Days 31-45: Override Reduction & Validation

The final two weeks focus on measuring and reducing manual override frequency. Fewer manual overrides by employing machine learning from a broader set of information that informs decision-making becomes achievable when the system learns from dispatcher feedback rather than operating in isolation.

Implement override tracking with required reason codes. When dispatchers modify AI recommendations, capture the specific reasons: driver preference conflicts, customer requirements, equipment issues, or route constraints. This feedback becomes training data for machine learning improvements.

Configure validation workflows that test optimization accuracy before full deployment. Run parallel systems where AI recommendations are compared against dispatcher decisions for two weeks. Analyze discrepancies to identify systematic bias or constraint gaps in the optimization engine.

Establish performance monitoring protocols during the final week. Track override frequency, recommendation acceptance rates, and dispatcher satisfaction scores. Set baseline metrics for measuring long-term success: target 60% reduction in manual overrides within 90 days of full deployment.

Critical Success Factors & Common Pitfalls

Implementation success depends on avoiding common mistakes that undermine optimization adoption. The most critical requirement is no data delays across systems. Even 30-minute delays in driver status updates can trigger manual overrides that cascade through daily planning operations.

Flexible constraint adjustment capabilities prevent dispatcher frustration. The user can flexibly adjust constraints and run the optimization again instantly when unexpected changes occur. Systems that require complex configuration changes or engineering support for routine adjustments inevitably face adoption resistance.

Training approaches matter more than training duration. Focus on teaching load planners when to trust AI recommendations rather than forcing system adoption. Experienced dispatchers possess valuable tribal knowledge about customer preferences, driver capabilities, and operational constraints. The optimization system should augment this expertise, not replace it.

Vendor support strategies vary significantly across TMS platforms. Oracle TM and SAP TM typically require extensive consulting services for optimization configuration, while solutions like Cargoson offer more self-service configuration capabilities. Factor implementation support requirements into your platform selection process.

More than 50% of TMS adopters see positive ROI within 18 months, but that leaves a substantial portion of companies wrestling with disappointing results. Most failures result from poor integration planning rather than inadequate AI capabilities. Spend 60% of your implementation time on data architecture and workflow integration, not feature configuration.

Measuring Override Reduction Success

Establish baseline metrics before optimization deployment to measure improvement accurately. Track manual override frequency, categorized by reason: driver constraints (typically 35% of overrides), customer requirements (25%), equipment issues (20%), route optimization disagreements (15%), and other factors (5%).

Monitor planning accuracy through key performance indicators that reflect real operational impact. Measure recommendation acceptance rates, planning cycle time reduction, and dispatcher satisfaction scores. Is your dispatcher or planner able to do more in a day with the new system? ROI is all about knowing how you were doing before, quantifying the as-is state and what it costs you, and then, as you implement, measuring what it looks like in the new state and validating that you, in fact, got the savings expected.

Create ROI calculation frameworks that capture both direct cost savings and productivity improvements. Direct savings include reduced deadhead miles, improved fuel efficiency, and decreased detention charges. Productivity gains encompass faster planning cycles, reduced manual data entry, and improved dispatcher capacity utilization.

Configure dashboard visualizations that provide real-time visibility into optimization performance. Display override frequency trends, recommendation accuracy scores, and cost savings metrics in formats that operations managers can quickly interpret. Include drill-down capabilities that help identify specific improvement opportunities.

Sample SQL queries for extracting override metrics from your TMS database:

```sql

SELECT override_reason, COUNT(*) as override_count, AVG(cost_impact) as avg_cost_impact FROM dispatch_overrides WHERE override_date >= DATEADD(day, -30, GETDATE()) GROUP BY override_reason ORDER BY override_count DESC ```

Track leading indicators that predict optimization success: data feed reliability, constraint accuracy, and user engagement metrics. Systems with 95%+ data feed uptime and 80%+ recommendation acceptance rates typically achieve target override reduction within 60 days.

Troubleshooting Guide: When Overrides Still Happen

Even well-implemented systems face scenarios where manual overrides remain necessary. Plans become obsolete the moment they're created when unexpected events disrupt scheduled operations. The key is distinguishing between systematic optimization failures and legitimate override scenarios.

Emergency override protocols should maintain optimization integrity while accommodating urgent changes. Configure "fast re-optimization" capabilities that automatically recalculate assignments when high-priority overrides affect multiple loads. This prevents single changes from cascading through the entire daily plan.

Common troubleshooting scenarios include driver availability conflicts where ELD data lags real-time status changes. Implement 15-minute data refresh cycles and configure exception alerts when driver status changes aren't reflected in optimization recommendations within 30 minutes.

Customer requirement conflicts often trigger overrides when optimization engines don't access real-time delivery window changes. Establish direct API connections with customer portals or require confirmation steps before finalizing recommendations that conflict with recent customer communications.

Escalation procedures should provide clear paths for resolving optimization engine limitations. Making adjustments requires either waiting days for engineering support or manually overriding the system represents a common implementation failure. Configure self-service constraint modification capabilities that allow dispatchers to adjust optimization parameters without technical support.

Document systematic override patterns that indicate optimization engine deficiencies rather than operational exceptions. When specific customer accounts, driver pools, or route corridors consistently trigger manual overrides, these patterns reveal opportunities for constraint refinement or machine learning improvements.

Future-Proofing Your Optimization Setup

Transportation management continues evolving toward greater automation and intelligence. The BeyondTrucks Optimization Solution is designed for the real-world complexities of the highly dynamic context in which fleets operate provides a model for building adaptable optimization systems.

Autonomous vehicle integration represents the next major disruption to dispatch optimization. Alabama-based McLeod said the integration will enable mutual customers to utilize their McLeod TMS to manage critical processes such as load tender and acceptance of autonomous shipments, dispatch, and load visibility. Configure your optimization architecture to accommodate autonomous vehicle scheduling requirements: continuous operation capabilities, precise pickup/delivery timing, and automated route coordination.

Scalability considerations become increasingly important as freight volumes grow and optimization complexity increases. Cloud-based TMS platforms offer advantages for handling volume fluctuations, but data architecture decisions made during initial implementation affect long-term scaling capabilities.

API standardization enables easier integration with emerging technologies and services. Choose TMS platforms that support open API architectures and provide comprehensive integration documentation. This flexibility allows incorporation of new optimization algorithms, data sources, and workflow tools without major system redesign.

The integration landscape continues expanding as more specialized services enter the market. We have seen a real explosion of integration requests and requirements. More and more companies are coming into the market providing information services, and the pace of change is accelerating. Build your optimization setup with modular integration capabilities that accommodate new service providers without disrupting core operations.

Success in TMS dispatch optimization comes from treating it as a workflow integration challenge rather than a technology deployment project. The 45-day framework addresses the integration gaps and user adoption barriers that cause manual override problems while building the foundation for sustainable optimization improvements. Start with data architecture, focus on workflow integration, and measure success through reduced override frequency rather than AI sophistication metrics.